Setup of Swiss Type broach holders:

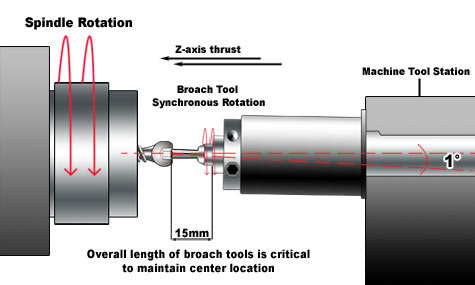

The 2100 and 2160 Swiss type holders do not require centering with an indicator. These heads are designed for machines with more accurate centering built into the machine. This would include Swiss Type CNC, Gang type, and small precision lathes, all of which are designed for small diameter precision turning. It is not generally recommended to use the 2100 series broach head on conventional CNC turret type lathes due to the centering inaccuracy associated with these lathes. With the 2100 series broach head it is essential to use the correct length broach. The overall length of the broaching bit is 28mm +0,30 -0,0 and the shank diameter is 8mm with an h5 tolerance. Failure to use the correct length or to bottom out the broach will result in poor broach size, & quality.

All 2110 Series Broaches are tightly controlled on the Overall Length Tolerance to ensure proper center location when used in Swiss-Type Rotary Broach Holders