|

||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

Rotary Broaching Holders & Attachments |

||||||||||||||||

|

||||||||||||||||

| Precision Manufactured by PCM® Willen SA of Switzerland |

||||||||||||||||

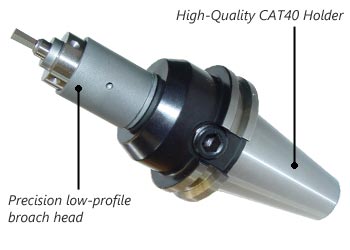

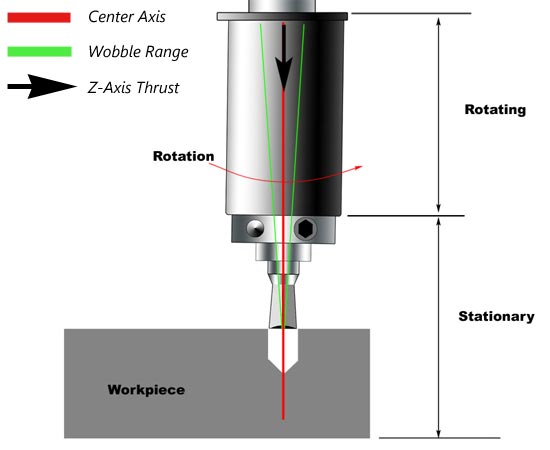

| 2160 Series Broach Holder - VMC Configuration Rated to 2250 thrust lbs. - Holds 8mm shank 2110 series broaches |

||||||||||||||||

Europe's best Swiss Made broaching products, now available to US customers |

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||